Adhesive Solutions for Power Semiconductors

IGBT, Thyristor, Thyristor, Adhesive Seal, Gel Potting, Thermal Grease

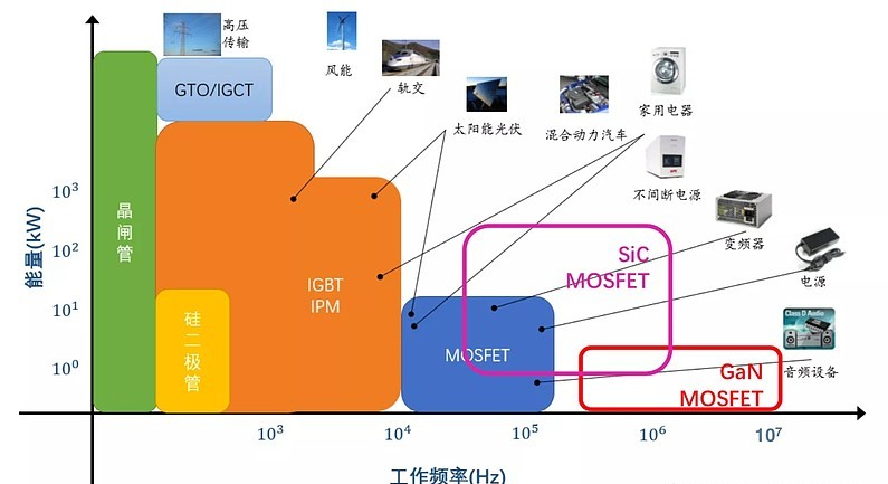

The application fields of the above components can be seen in the following figure:

On the demand side, about 40% of the world's power semiconductor device production capacity is consumed by China, the world's largest demand country, but its self-sufficiency rate is only 10%, heavily dependent on imports.

Proportion of IGBT applications in various fields

Adhesive solutions for power devices on the market:

- Border sealant: single component room temperature curing silicone or single component addition silicone

- Chip protection adhesive: two-component silicone gel at room temperature

- Surface protection adhesive: two-component epoxy adhesive

- Border sealant: single component room temperature silicone 7338 and single component plus molding 7435

- Surface protection adhesive: two-component high-temperature epoxy adhesive 3115

- For chip protection launched 6606, because the power module with this glue point market mainstream products are 527, 612 and 3062

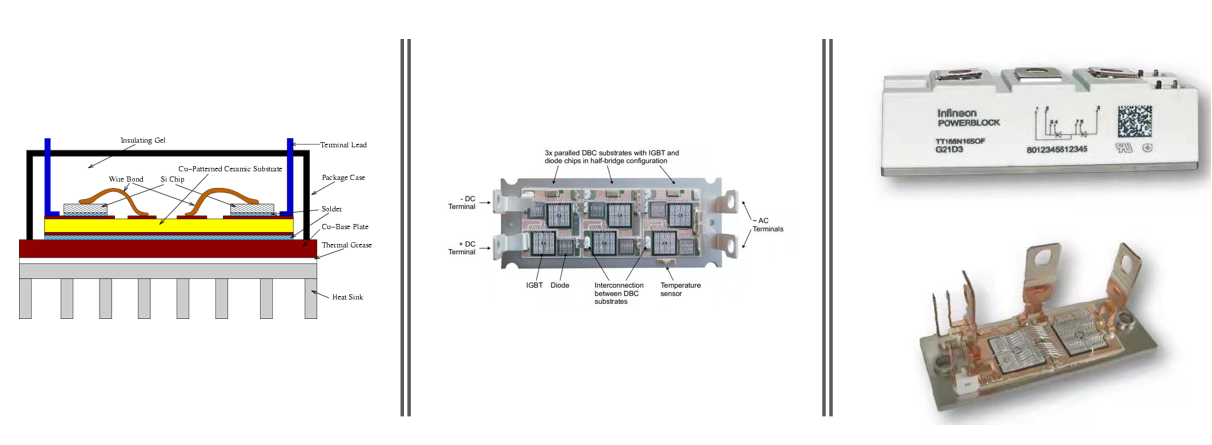

Product structure breakdown diagram

Rectifier bridge

Application:

- Border seal: 7338 single component silicone sealant, transparent, quick drying, moisture curing. 7435 Single component heat curing. Chip glue protection: depending on the product requirements, 6230 can be used if the requirements are not high, and 6606 is required. Surface high temperature hard epoxy adhesive: 3115 two-component hot curing or room temperature curing.

- Thyristor adhesive Application: 1:Border seal: MDSI 7338 Single component silicone sealant, transparent, quick drying, moisture curing. MDSI 7435 single component heat curing.

- Surface high temperature hard epoxy adhesive: MDEP 3115 two-component heat curing or room temperature curing.

IGBT module adhesive

Application: 1:Border seal: MDSI 7338 Single component silicone sealant, transparent fast drying and wet gas curing. MDSI 7435 single component heat curing. 2: Chip glue protection: MDGEL 6606 two-component silicone gel, long opening time, wide temperature range and high reliability 3:Surface hard epoxy adhesive: DEP 3115 Two-component heat curing or room temperature curing 3112.