Solution of electromagnetic induction module adhesive

One of the most important applications of electromagnetic induction is the manufacture of generators, the basic principle is: a part of the closed circuit is wound into a coil, and then rotation in the magnetic field to cut the magnetic induction line, resulting in induced current, electromagnetic induction phenomenon is everywhere in life, electromagnetic induction principle is used in many equipment and systems, including induction motors; A generator; Transformer; Contactless charging of rechargeable batteries; Electric furnace with induction frame; Induction welding; Inductor; Electromagnetic forming, etc.

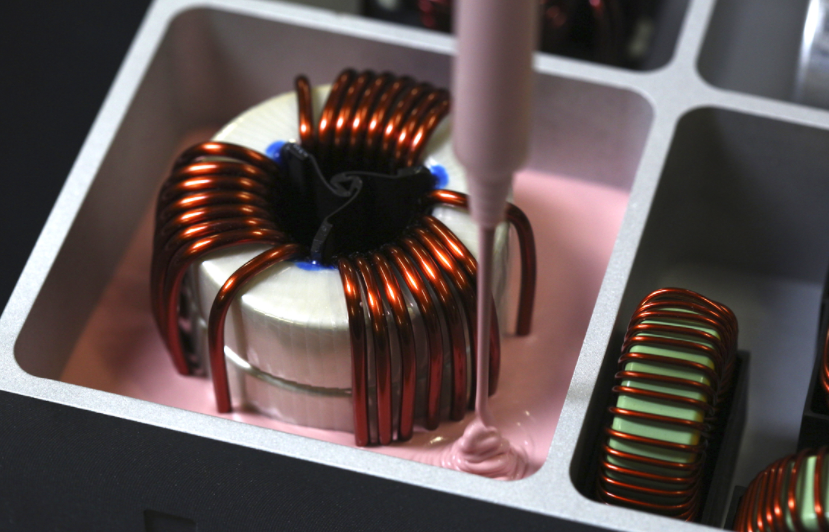

MDTECH has developed a series of adhesive solutions for electromagnetic induction, including: welding machine components fixed, coil heat conduction potting; Potting of reactor; Plastic seal of relay; Perfusion sealing of transformer; Permanent magnet suction cup wear-resistant potting and coil potting; Resistor hole filling, square resistance potting, tube sealing and air conditioning resistance potting.

Why do you need encapsulation?

Components may be affected by various environmental conditions during operation, such as moisture, dust, chemicals, etc. The use of sealant can help protect the electrical and electronic components inside the relay, improving the durability, protection and reliability of the relay.

▶Waterproof and moisture-proof: Usually used in a variety of environments, including wet conditions. The sealant can form a waterproof and moisture-proof barrier to prevent moisture from seeping into the interior of the relay, thereby reducing the corrosion and damage to electrical components in a humid environment.

▶Dustproof: The sealant can effectively prevent dust and particles from entering the device, prevent dust from polluting the electrical connection and components, and improve the reliability and life of the product.

▶Chemical protection: There are chemicals in some environments that may cause corrosion or damage to the components inside the device. The sealant provides a layer of protection that reduces chemical intrusion and ensures reliability in harsh environments.

▶Seismic and vibration resistance: the sealant can fill the internal gap and improve its mechanical strength, thereby improving the seismic and vibration resistance of the relay. This is particularly important for vehicles, mechanical equipment and other occasions with large vibration.

▶Insulation performance: Some sealants have excellent insulation properties, which can help the relay maintain stable electrical performance in a humid environment and avoid problems such as leakage caused by humidity.

▶Temperature stability: The sealant usually has a certain resistance to high and low temperatures, which can help the relay to maintain normal operation under extreme temperature conditions.